|

|

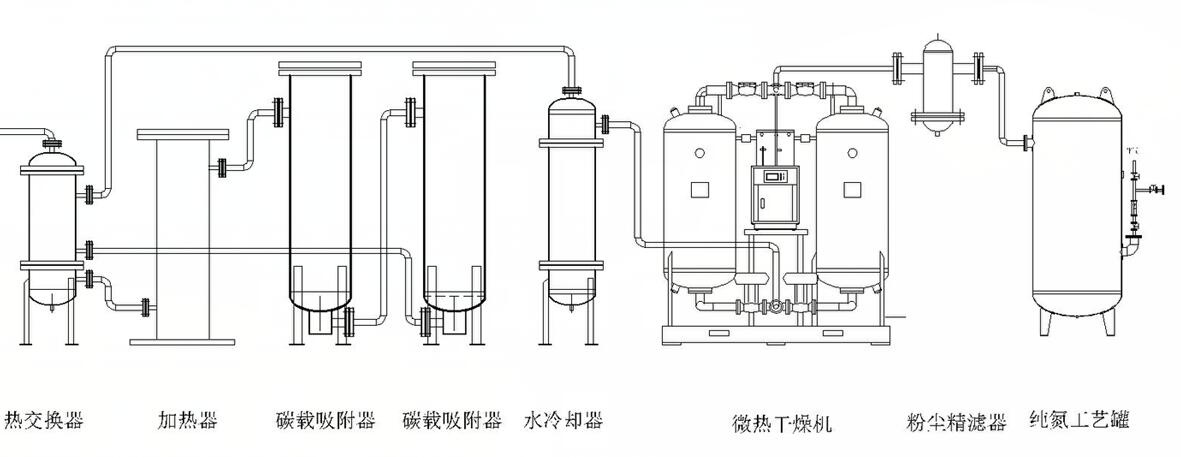

Introduction: HTC nitrogen and carbon purification nitrogen generator is based on PSA pressure swing adsorption nitrogen generator with a carbon-loaded purification device, which improves the purity of the original nitrogen to ≥99.999% high-purity nitrogen, which is provided for special industries Personalized and professional high-purity nitrogen production equipment and installation and application solutions, and provide after-sales service during equipment operation, fully meet the gas requirements of different users, quickly solve user problems, and ensure long-term, stable and reliable nitrogen production equipment run. working principle The working principle of PSA nitrogen production: Using high-quality carbon molecular sieve as the adsorbent, nitrogen is produced from the air under a certain pressure. The clean compressed air from the air buffer tank enters the pressure swing adsorption separation system filled with adsorbent in the absorption tower, and performs pressure adsorption and decompression desorption in the adsorber. Due to the kinetic effect, the diffusion rate of oxygen in the pores of the carbon molecular sieve is much greater than that of nitrogen. When the adsorption does not reach equilibrium, the nitrogen is enriched in the gas phase to form the finished nitrogen. Then the pressure is reduced to normal pressure, and the adsorbent desorbs the adsorbed oxygen and other impurities to realize regeneration. Generally, two adsorption towers are installed in the system. One tower absorbs nitrogen and the other tower desorption and regeneration. The two towers are automatically controlled by PLC program to make the two towers work alternately to achieve continuous production of nitrogen with a purity of ≥99.9%. Nitrogen carbon-carrying purification system: carbon-carrying purification device, the general nitrogen from the nitrogen buffer tank, the high-temperature nitrogen from the preheater and the deaerator is heat-exchanged, and then heated to a certain temperature by the heater, then enters the filling With the carbon catalyst deoxidizer, the residual oxygen in carbon and nitrogen reacts to form carbon dioxide, then enters the static mixer-type cooler to cool to normal temperature, and then uses the principle of pressure swing adsorption to remove carbon dioxide and carbon dioxide with a micro-heat regeneration dryer filled with molecular sieve After the water is finally filtered through an ultra-precision filter, high-purity nitrogen is obtained. In addition, the preheater (heat exchanger) installed in the purification device can recover the heat of the nitrogen after deoxygenation in the deaerator, which can greatly save energy consumption by more than 30%. At the same time, the cooler adopts a static mixer structure, which avoids the failure problem caused by the deformation of the conventional cooler tube and greatly improves the continuous operation and performance of the device. The final nitrogen purity is ≥99.999%. Technical index: Nitrogen output: 5-3000 Nm3/h Nitrogen purity: 99.999% Nitrogen pressure: 0.6-0.7Mpa Dew point: ≤-60℃ (under normal pressure)

Main features of HTN variable pressure nitrogen generator: 1. Perfect fluent design, optimal use effect; 2. Reasonable internal components, uniform airflow distribution, reducing the impact of high-speed airflow; 3. The unique protection measures of molecular sieve extend the service life of carbon molecular sieve; 4. Simple operation, stable operation, high degree of automation, and can be operated without anyone; 5. Automatic interlocking nitrogen exhaust device to ensure the quality of product nitrogen; 6. Optional nitrogen device flow, automatic purity adjustment system, remote monitoring system, etc.; Application scenario Electronics industry: Nitrogen protection for the production of semiconductors and electronic components Heat treatment: bright annealing, protective heating, powder metallurgy and magnetic material sintering, etc. Chemical industry: nitrogen blanketing, replacement, cleaning, pressure conveying, chemical reaction agitation, chemical fiber production protection, etc. |